Key points

Rapidly expanding use of Additive Manufacturing (3D Printing) can expose workers to potential safety and health hazards. NIOSH conducts research and provides recommendations for workers to support the safe and responsible deployment of this technology.

Overview

Additive manufacturing technologies are rapidly expanding in use and accessibility. Large numbers of people use this technology daily. Additive manufacturing technologies pose potential hazards to users. NIOSH is performing research to understand and minimize potential health and safety risk to workers.

Definitions

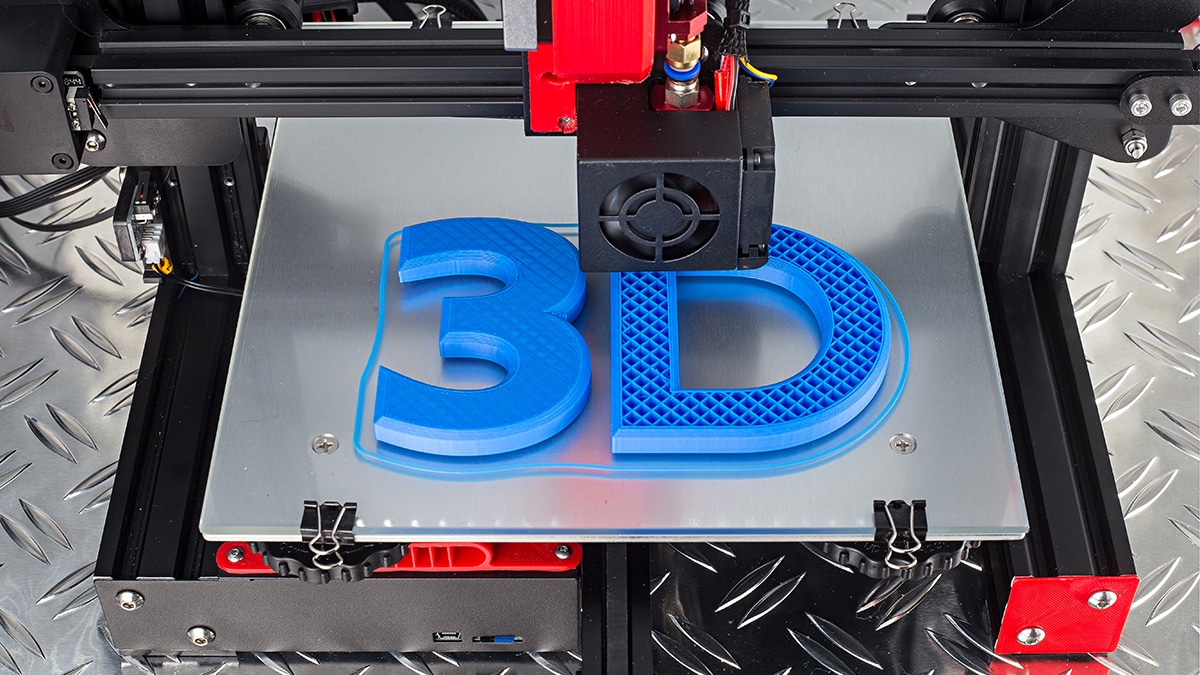

Additive manufacturing (also called 3-dimensional or 3D printing) is a set of technologies that assemble objects from smaller pieces of material. Examples of these technologies include fused filament fabrication, vat polymerization, or powder bed fusion.

Once just used for prototyping, these techniques are becoming less expensive and are used in production. Additive manufacturing techniques affect the automotive, aerospace, electronics, medical, and consumer markets.

What are the types of hazards?

Additive manufacturing hazards vary widely depending on the technology, materials used, and the environment they are used in. Hazards include:

- Inhalation of materials used in powdered form may occur. Materials may emit volatile organic compounds (VOC's) during 3D printing.

- Dermal exposure to powdered and liquid hazardous materials.

- Risk of fire or explosion from flammable or combustible substances.

- Mechanical or ergonomic injury from machine support and maintenance, loading and handling of build materials, and handling of products.

What is NIOSH doing to help?

NIOSH is conducting research on safe additive manufacturing to identify knowledge gaps, to develop robust science necessary to advance understanding in the field, and to best apply these developments in order to protect workers.

One pillar of this effort is traditional, laboratory-based research to answer key questions and solve major problems for safe additive manufacturing.

Laboratory studies have indicated that:

- Fused filament fabrication desktop printers emit respiratory irritants

- Filament material and coloration significantly affect volatile organic compound emission rates

- Printing with nanomaterial containing filaments lead to emission of nanomaterial containing particulate matter.

A second pillar is comprehensive exposure assessments performed by the NIOSH Nanotechnology and Advanced Materials Field Studies Team at ten different additive manufacturing sites. Fieldwork allows NIOSH to fill knowledge gaps on real-world technologies, uses, and exposures.

NIOSH continues to perform both laboratory and field studies to determine the hazards and potential for worker exposures while using emerging technologies such as additive manufacturing. Please reach out to us if you are interested in finding out more information or having this team visit your facility.

NIOSH is developing a series of "Additive Manufacturing Health Safety" videos. These videos will provide information on additive manufacturing/3D printing processes and safety and health information.

This is the first in a series of videos that NIOSH is producing on additive manufacturing. In this video, we provide an overview of additive manufacturing/3D printing processes and safety and health information. Content includes common hazards, control strategies, and current NIOSH resources. This video will be helpful to both additive manufacturing professionals or hobbyists working with 3D printers at home.

Resources

- Approaches to Safe 3D Printing: A Guide for Markerspace Users, Schools, Libraries, and Small Businesses

- How to Reduce Exposures When 3D Printing with Plastic Filament - Infographic

- Safe Desktop Vat Photopolymerization 3-D Printing - Infographic

- 3D Printing with Metal Powders: Health and Safety Questions to Ask

- 3D Printing with Filaments: Health and Safety Questions to Ask

- Evaluation of 3-D Printer Emissions and Personal Exposures at a Manufacturing Workplace

- NIOSHTIC-2 search results on Advanced Manufacturing. NIOSHTIC-2 is a database of occupational safety and health publications funded in whole or in part by NIOSH.

To print these images

Postcard: 7.50 x 4.50 inches

Sticker: 2.5 x 2.5 inches

- Stefaniak A, LeBouf R, Yi J, Ham J, Nurkewicz T, Schwegler-Berry D, Chen B, Wells J, Duling M, Lawrence R, Martin S, Johnson A, & M. Virji M. (2017) Characterization of chemical contaminants generated by a desktop fused deposition modeling 3- dimensional Printer, Journal of Occupational and Environmental Hygiene, 14:7, 540-550, DOI:10.1080/15459624.2017.1302589

- Stephens B, Azimi P, El Orch Z, & Ramos T. Ultrafine particle emissions from desktop 3D printers. (2013) Atmospheric Environment, (79) 334-339. https://doi.org/10.1016/j.atmosenv.2013.06.050

- Yi J, Duling M, Bowers L, Knepp A, LeBouf R, Nurkiewicz T, Ranpara A, Luxton T, Martin S, Burns D, Peloquin D, Baumann E,Virji M, & Stefaniak A. (2019) Particle and organic vapor emissions from children's 3_D pend and 3-D printer toys, International Forum for Respiratory Research, 31:13-14, 432-445, DOI: 10.1080/08958378.2019.1705441

- Dunn KL, Dunn KH, Hammond D, & Lo S. (2020) Three-dimensional printer emissions and employee exposures to ultrafine particles during the printing of thermoplastic filaments containing carbon nanotubes or carbon nanofibers. Journal of Nanoparticle Research. 22, 46 (2020). https://doi.org/10.1007/s11051-020-4750-8