Key points

- Employers are required to minimize lead exposure among their employees.

- Employers must ensure lead exposure limits are not exceeded.

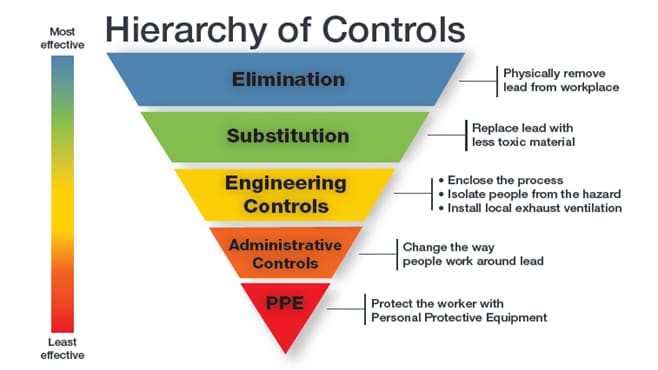

- Follow steps in the hierarchy of controls to reduce lead exposure.

About lead exposure limits

Workplace exposure limits are meant to protect workers from hazardous exposures in the workplace. Exposure limits incorporate safety margins. This helps ensure that workers won't be overexposed to hazardous chemicals or materials. Employers must ensure exposure limits are not exceeded.

Recommended exposure limit (REL)

NIOSH develops recommended exposure limits (RELs) for hazardous substances or conditions in the workplace.

NIOSH's REL for lead is a TWA of 50 µg/m3 of air over an 8-hour work shift.1

TWA = Time-weighted average

µg/m3 = micrograms per cubic meter of air

Permissible exposure limit (PEL)

The Occupational Safety and Health Administration (OSHA) has permissible exposure limits (PELs) for hazardous materials. PELs are legal limits that are enforceable in workplaces. They are covered under the Occupational Safety and Health Act of 1970.

OSHA's PEL for lead states lead exposure cannot be greater than 50 µg/m3 as a TWA over an 8-hour work shift.2 If working shifts longer than 8 hours, the exposure limit is reduced using the equation PEL = 400/hours worked.

For example:

- The PEL for a 10-hour work shift: (400/10) would be 40 µg/m3

- The PEL for a 12-hour work shift: (400/12) would be 33.3 µg/m3

Action levels

The action level for lead is a TWA of 30 µg/m3 over an 8-hour work shift. This applies to general industry and the construction industry.

Employers must begin specific compliance activities if employee lead exposure is above the OSHA action level. This includes blood lead testing, air monitoring, and other practices critical in preventing lead exposure and elevated blood lead levels.

- See OSHA Lead Standards for actions required to keep workers safe.

- Contact your state OSHA office for state-specific requirements.

Protect your workers from lead

Determine if lead is present

Examine the work area and the task(s) your workers perform to determine if work materials and equipment contain lead.

Review Safety Data Sheets (SDSs) or test to determine if lead is present. Employers must keep SDSs for each chemical used in the workplace. These sheets will tell you if lead is present in a chemical. Learn more about the format and contents of Safety Data Sheets.

If lead is present, use the hierarchy of controls to figure out the most effective way(s) to control exposures.

The hierarchy of controls are listed in order of the most effective to least effective ways to reduce lead exposure.

Elimination

Eliminate the lead source (physically remove the lead source from the workplace). Where possible, remove lead-containing materials or equipment from the process.

Substitution

Substitute the lead source with a material that is less toxic or has a lower lead content. For example, use lead-free bullets in place of leaded bullets or lead-free solder.

Engineering controls

Engineering controls ensure the work area or equipment is designed to keep lead away from the worker.

For example:

- Enclose or isolate the lead emission source.

- Use local exhaust ventilation to draw airborne lead away from the employee’s work area.

Engineering controls must be maintained and operated properly to be effective.

Administrative controls

Administrative controls modify the way people work.

For example:

- Establish standard operating procedures for tasks that would expose workers to lead.

- Implement strict housekeeping practices to minimize lead dust in the air and on surfaces.

- Use HEPA vacuums or wet sweeping methods.

- Do not use dry sweeping methods.

- Provide employee training on hazards and safe work practices when working with lead.

- Direct employees to follow good hygiene practices.

- Encourage workers to use lead-removal products, wash their hands, and shower.

- Prevent workers from taking home contaminated work clothing and equipment.

- These practices can reduce take-home lead, which also puts workers' families at risk.

Personal protective equipment (PPE)

Provide PPE to your workers if the other control methods are insufficient, or while better control methods are being implemented.

- PPE may include eye protection, gloves, boots, coveralls, and respiratory protection.

- Employers should also provide methods to clean or dispose of contaminated PPE.

Resources to keep workers safe

NIOSH Health Hazard Evaluation (HHE) Program

If you are concerned about your employees' lead exposure or another workplace hazard, contact the NIOSH Health Hazard Evaluation Program. You can submit a request to have the work environment evaluated for free.

OSHA Consultation Program

Employers may also contact the OSHA Consultation Program, a free consultation service funded by OSHA. Through the program, you can learn about potential hazards at your worksites and improve your occupational safety and health management systems.

- NIOSH researchers developed wipes that remove 90% of lead residues from skin. NIOSH researchers also developed a quick and easy hand wipe technology to let workers know instantly if they have lead on their hands.

- Contact us if you are interested in partnering with NIOSH to license this technology.