Key points

- Between 2000 and 2019, 122 fishermen experienced fatal injuries onboard fishing vessels, representing 14% of all fatalities.

- The leading cause of these fatalities is contact with gear, equipment, and machinery (40%).

- Other causes included falls, electrocutions, and exposure to harmful substances or environments (e.g., oxygen deficiency; hydrogen sulfide).

- Non-operational fatalities, such as suicides, homicides, and unintentional drug overdoses also occurred (35%).

What do we know about onboard injuries?

Injuries occurring on a vessel (i.e., not related to a vessel disaster or fall overboard event) are a significant contributor to fatalities and hospitalizations among fishermen. Wet, pitching decks result in many slips, trips, and falls.

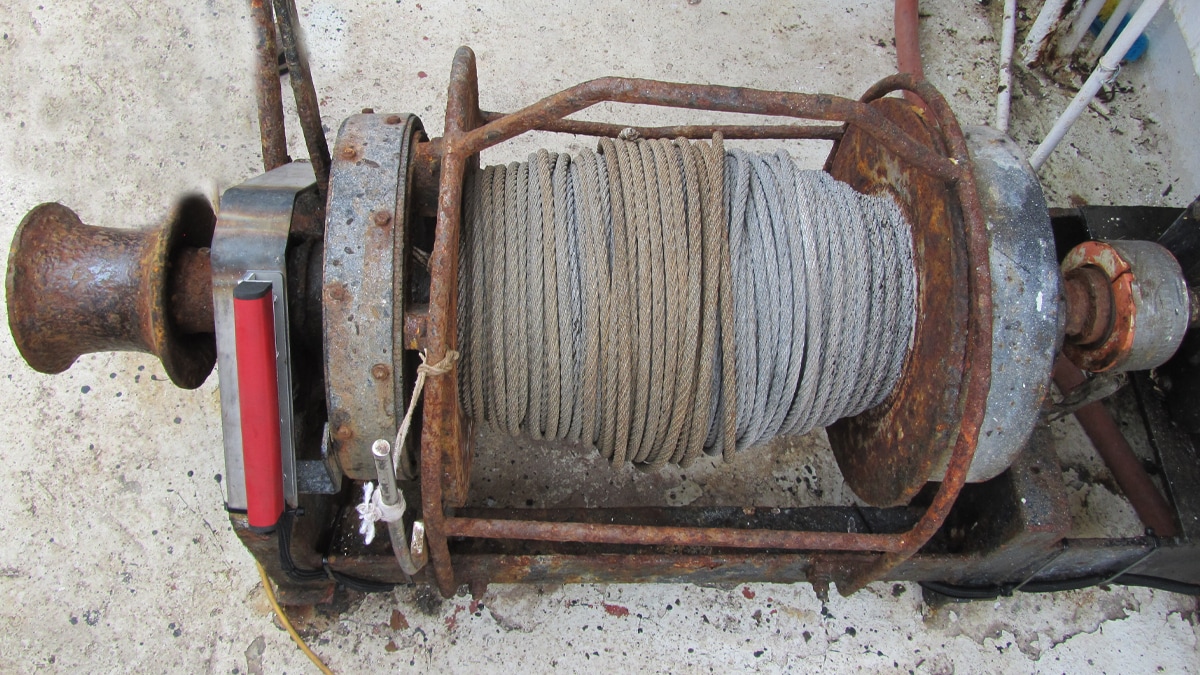

High tension lines and cables running through hydraulic haulers and winches can lead to contact injuries including amputations and death. Working with gear and pulling in lines over long hours exposes fishermen to ergonomic hazards.

NIOSH researchers have also examined nonfatal injuries in specific fisheries. In Alaska, fishermen most commonly reported injuries when hauling gear, often resulting in sprains, strains, tears, lacerations, and fractures.

An analysis of injuries reported to the Coast Guard by West Coast Dungeness crab fishermen revealed that, of these serious injuries, fractures were the most common injury type, often resulting from working with crab pots and pulleys. Shrimp fishermen in the Gulf of Mexico work with hazardous deck winches that can cause fatal or severe, disabling injuries from entanglement.

Seafood processors sometimes work onboard fishing industry vessels and are also at risk of experiencing injuries. These workers can be exposed to repetitive motion, manual materials handling, long working hours, and other ergonomic risk factors.

What is being done

NIOSH research in preventing onboard injuries

NIOSH has approached reducing these injuries on-deck through a combination of hazard awareness and engineering interventions. NIOSH engineers developed an emergency stop device for purse seine vessels in the Pacific Northwest. The device is commercially available on capstan winches through Kolstrand Marine, and can be added to existing winches. The emergency-stop has been adopted by the salmon seine fleet.

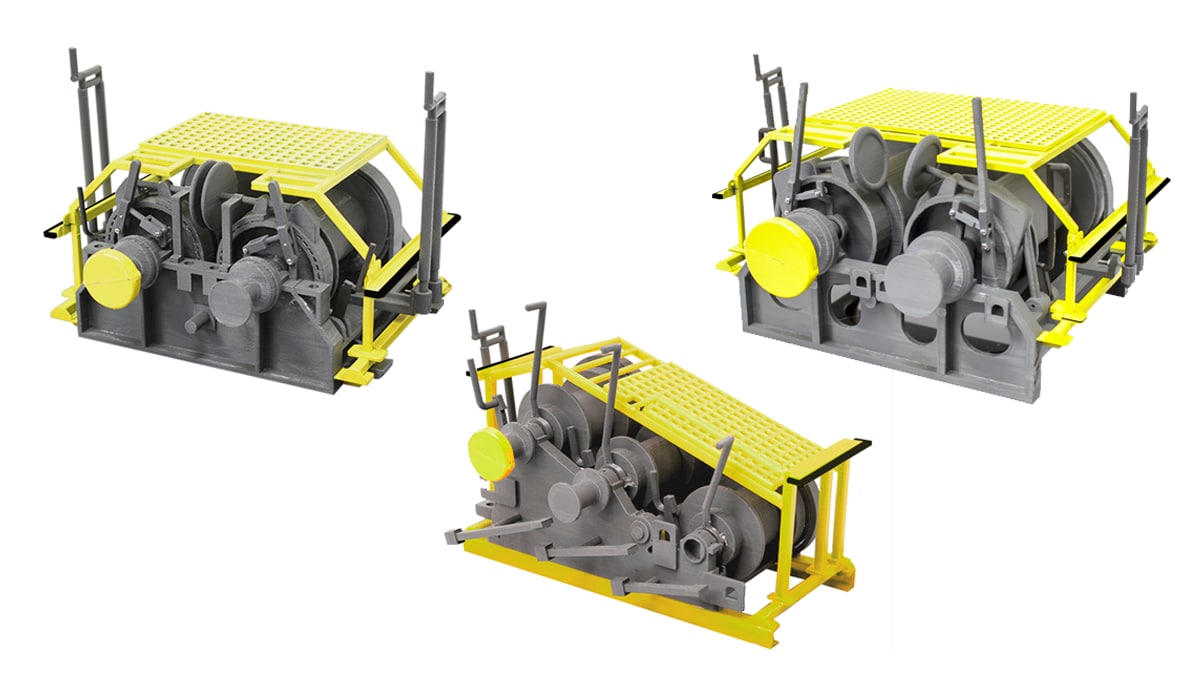

NIOSH prototype static winch guarding

NIOSH researchers discovered that shrimp fishermen in the Gulf of Mexico were at high risk of death and disabling injuries from winch entanglements. Engineers developed static winch guards (shown below) for three common types of main deck winches. These guards put a physical barrier between the rotating winch and the worker to prevent entanglements while not interfering with fishing operations.

Resource

NIOSH prototype stop switch for a try-net winch

NIOSH engineers have collaborated on developing a solution for try-net winches. An auxiliary stop switch should be easily accessible and allow for an entangled crewmember to shut off the electrical power to the winch, even if working alone.

What you can do

- Install safety devices on deck machinery. Emergency-stop buttons have been developed specifically for deck machinery on fishing vessels and can be adapted and retrofitted onto winches or other machinery.

- Eliminate slip and trip hazards. Inspect the deck and other walking surfaces periodically to identify and eliminate slippery areas. Non-skid gratings, fiber mats, and nonslip coatings can be used.

- Develop safe work practices and policies. Procedures for work tasks, such as working with winches or maintenance operations, should be developed with crewmembers. All crewmembers should receive training in these procedures.

Resources

OSHA has developed a series of fact sheets on commercial fishing and ship repair addressing other on-board hazards including falls, confined spaces, and working with refrigerants.

The RISC Fishing Project has fact sheets on the leading injuries in the Pacific Northwest fishing fleet and hazard assessment worksheets for use by fishing crews.

The Northeast Center for Occupational Health and Safety has multiple commercial fishing safety projects, including an ergonomic study to reduce back pain among lobstermen.

Fishing Forward is a podcast for fishermen with a focus on health and safety. Fishing Forward is funded by the Northeast Center for Occupational Safety and Health and produced by Coastal Routes Radio at the University of Guelph.