What to know

Why it's important

Occupational exposure limits (OELs) indicate the maximum allowable concentration of a chemical substance within the workplace. Levels at or above the OEL can increase the risk of workplace exposure. OELs include NIOSH Recommended Exposure Limits (RELs) and OSHA Permissible Exposure Limits (PELs). Most chemicals in commercial use have not been assigned an OEL.

Repeated occupational exposure to a chemical, even below its OEL, may not lead to harmful health effects in most workers. Many commercially available chemicals and chemical mixtures have not been assigned an OEL from an authoritative source.

Control Banding Process

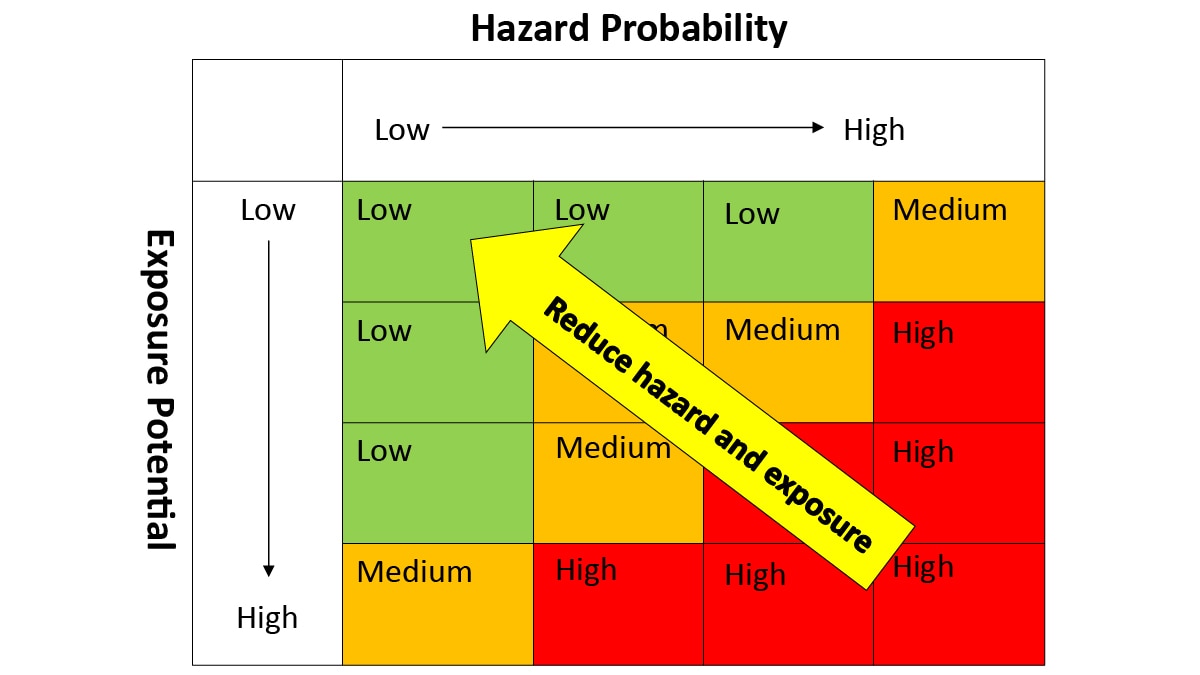

Workplace risks are grouped into control categories or “bands” based on assessing hazard and exposure information.

A "band of hazards" might be:

- skin/eye irritant,

- very toxic, or

- carcinogenic, among others.

The potential for exposure (low, medium, high) is also considered. The exposure potential includes the following considerations:

- duration of task,

- amount of chemical handled,

- or the form of the chemical.

At the end of the control banding process, users have a proposed control measure to implement (see example matrix).

Control measures serve to decrease risk. Examples of recommended control measures could be personal protective equipment, dilution ventilation, engineering controls, containment, or some other hazard control. This approach is based on two pillars:

- there are a limited number of control approaches,

- and many problems have been met and solved before.

Control banding uses the solutions that experts have developed previously to control occupational chemical exposures and suggests applying them to other tasks with similar exposure situations. It is an approach that focuses resources on exposure controls and describes how a risk needs to be managed. NIOSH considers control banding to be a potentially useful tool for small businesses.

Control banding is best used with the hierarchy of controls, which aims to protect workers by reducing exposure to hazards in the workplace. For example, a hazardous chemical can be substituted with a less hazardous chemical.

It is important to note that control banding is NOT a replacement for experts in occupational safety and health. Sometimes the control banding advice directly guides employers to seek expert guidance.

Specific operating knowledge and professional judgment are required to implement the best combination of controls that are “reasonably practicable” and to minimize risks to workers. Control banding also does not eliminate the need to perform exposure monitoring.

How is control banding different than occupational exposure banding?

Control banding and occupational exposure banding are both techniques for managing risk for chemicals that do not have an OEL. Occupational exposure banding uses the “banding” concept differently, applying hazard-based data (such as studies on human health effects or toxicology studies) to calculate which of five “bands” is appropriate. Each occupational exposure band (OEB) has an exposure limit range. After completing the OEB process, users must determine whether workplace exposures fall within that range. They must also decide what controls to put in place if the results exceed the range. Once controls are in place, it is important to perform exposure monitoring or assessment to verify the exposures no longer exceed the range of concern.

In contrast, control banding ends with specific exposure control and risk management strategies. Control banding can be used together with the OEB methodology. It’s important to note that any control banding or OEB needs follow up. These methods are not a replacement for health surveillance or environmental samples. In addition, this is not a process that should be performed only once. Routine follow-up should always be performed in addition to changes in tasks/process/materials.