What to know

When you can’t eliminate or lessen the noise, hearing protection can be quite effective when chosen correctly, fit well, and used consistently!

Understanding hearing protection

Employers should not rely on personal protective equipment (PPE) alone to control hazards when other effective control options are available. Employers should implement engineering and administrative controls first to reduce worker noise exposure. PPE is generally less effective than elimination, substitution, and engineering controls. Hearing protection is often:

- Inadequately chosen

- Worn incorrectly

- Used inconsistently

Employers can avoid these pitfalls by selecting appropriate hearing protectors and providing proper training. Training should ensure workers know where to use hearing protection and how to use them correctly. Follow hearing protection best practices:

- Provide workers with a variety of hearing protection options that will reduce noise exposure to less than the recommended exposure limit (REL) of 85 dBA.

- Select hearing protectors that are comfortable and compatible with the job, using the guidance in the next section. Reevaluate hearing protector options when working conditions and noise exposures change or when a worker develops a hearing shift.

- Train management as well as workers. Identify unique motivations for each group to prioritize hearing safety.

Hearing protector manufacturers include a noise reduction rating (NRR) on packaging, but this often does not reflect the actual protection provided for each worker. NIOSH has previously recommended derating the NRR as explained in the NIOSH criteria document on Occupational Noise Exposure. However, individual hearing protector fit testing is the best way to check if each worker is getting the amount of protection needed.

Choosing hearing protectors

Hearing protection comes in many styles, materials, colors, and sizes. The main types of hearing protectors include:

- Earplugs – devices which slide snugly into the ear canal. Earplugs can be formable (such as foam, which expand to fit the contour of the canal), pre-formed (which are already shaped to fit most ears), or custom (which use an impression of the worker's ear to make a device uniquely fitted to that person)

- Earmuffs – devices which completely surround the outer ear and are held in place by a headband or attached to a hardhat

- Canal caps – devices which cover the entrance to the ear canals and are held in place by a lightweight band.

Some hearing protectors have special features that are helpful for certain types of noise or work situations. Examples of these features are:

- Flat attenuation – these hearing protectors (sometimes called "musicians' earplugs) reduce noise equally across all frequency bands, which preserves the fidelity of the sound

- Non-linear – these hearing protectors (which include level-dependent and sound restoration hearing protectors) allow quiet sounds to pass through but block loud sounds

- Communication technologies – these hearing protectors have built-in microphones and speakers that make it easier to talk to other workers in a noisy environment

With all these choices, how can you know which is best for your workers?

Know how much hearing protection you will need

The most basic consideration is the noise exposure level. However, most workers need 10 dB or less sound reduction to bring their exposure down to a safe level. Almost any hearing protector, when fit correctly, can reduce noise by 10 dB. Keep the following guidelines in mind:

- Aim for just enough noise reduction to bring exposure down to 75-85 dBA.

- Avoid overprotection.

- Too much sound reduction can make workers less aware of their surroundings.

- Workers might take off their hearing protectors to hear properly.

- Provide double hearing protection (earmuffs over earplugs) for workers exposed to noise levels 100 dBA or greater or impulse sounds.

- Fit test workers to make sure their hearing protectors are providing the right level of noise reduction.

Consider the 5 "Cs" of selecting hearing protection

While reducing noise to a safe level is necessary, other factors are more important for making sure that workers will wear their hearing protection correctly and consistently. These factors include comfort, compatibility, convenience, communication, and cost.

Comfort: No one wants to wear something that is uncomfortable – especially for a long period of time. Comfort is the key to consistent use of hearing protection. Comfort is a personal choice; no single protector will be the most comfortable for all workers. However, the following principles are generally true:

- Earplugs are often more comfortable than earmuffs, especially when worn for long periods of time or in in hot environments.

- Earmuffs are heavier than earplugs and may be uncomfortable in warm places.

Compatibility: Hearing protection must be compatible with other safety equipment, characteristics of the work area, and the type of work being done. Consider possible problems:

- Earmuffs and canal caps can interfere with the fit of other protective equipment worn on the head, such as hardhats, helmets, respirators, eye protection, and even some eyeglasses.

- Some hearing protectors have accommodations for other PPE, such as muffs that can be mounted to a hardhat or bands that can be positioned behind the neck rather than over the head.

- Earmuffs may not be compatible with working in a confined area.

- Earmuff cushions do not seal against the head effectively in very cold environments.

Convenience: Think about the work environment and how workers will use their hearing protection during the day. Consider whether the noise is continuous or if it stops and starts, how often workers move from place to place during their work shift, and the cleanliness of the worksite. Workers are more likely to use their hearing protectors if you make it easy for them. In addition to the guidelines below, post signs in noisy areas to remind workers that hearing protection is required and keep a supply of hearing protectors readily accessible.

- Earmuffs, canal caps, and pre-formed earplugs are easier to take off and on if the noise stops and starts or workers move back and forth between noisy and quiet areas

- Level-dependent or sound restoration hearing protectors can also be useful for intermittent exposures.

- Earplugs are lightweight, easy to store, and convenient to keep on hand.

- Foam earplugs are not a good choice for intermittent use at dirty worksites because they must be rolled with fingers before insertion.

- Earmuffs are often easier to fit properly.

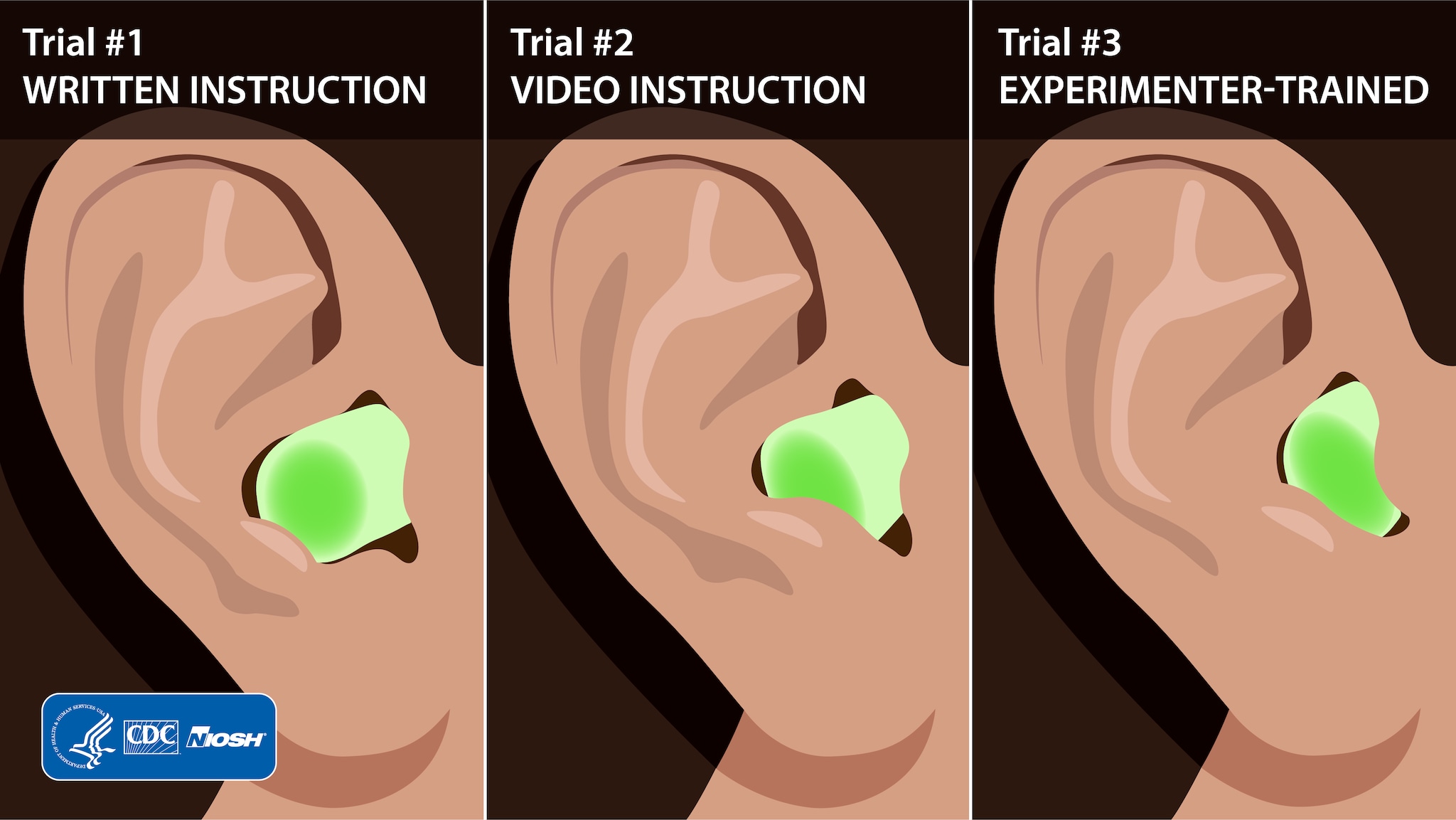

- Earplugs may be harder to learn to fit correctly.

Communication: Consider how often workers will need to hear others' speech while wearing hearing protection and how far apart the workers will be when they need to communicate. In some cases, equipment sounds may also be important for workers to hear.

- Flat attenuation hearing protectors may be helpful if verbal communication is common or if high fidelity sound is important.

- Special communication headsets can improve speech communication in very loud environments and are particularly helpful when workers are far apart from one another.

Cost: Cost is often a consideration, but sometimes more expensive hearing protectors can be cost-saving in the long run. Keep the following principles in mind:

- Hearing protectors that workers do not wear are not a good investment.

- Earmuffs and custom earplugs cost more at the outset but they are more durable and last longer than formable or preformed earplugs.

- Specialty devices such as flat attenuation hearing protectors and communication headsets are higher in cost, but may be worn more consistently, reducing threshold shifts and compensation costs.

Always have several options available for workers to try. Let them choose the hearing protector they like best from those that meet all the needs of their job. Remember to fit test to make sure the hearing protector they choose provides enough noise reduction to protect them from their noise exposure. For more guidance, see the NIOSH Science Blog on Three Tips for Choosing the Right Hearing Protector.

Fit testing

Fit testing is a great way to make sure people are wearing their hearing protectors correctly. It provides an estimate of the noise reduction obtained by the individual worker.

How does fit testing work?

- Hearing protector fit testing generates a Personal Attenuation Rating (PAR).

- A PAR estimates an individual worker's reduction in noise exposure when using that hearing protector.

- A worker's protected noise exposure may be determined by subtracting the PAR from the measured exposure level.

- A variety of hearing protector fit testing systems are available using different methods and technologies.

- Systems vary – follow the instructions for the chosen system.

Recommendations for fit testing

- Select an appropriate place to conduct the fit testing.

- Keep in mind that background noise can interfere with the testing, so select the quietest area possible.

- Provide a selection of various hearing protection devices to the worker.

- Provide the employee with individualized or personal instruction on fitting the hearing protectors and perform the fit test.

- If the fit test shows that the employee is not achieving sufficient noise reduction, provide additional training on how to insert earplugs.

- After assuring the employee is inserting them properly, repeat the test.

- If necessary, repeat the test with various hearing protection devices until the employee achieves adequate or optimal protection.

- Document the worker's ability to achieve adequate protection for a given hearing protector.

Educate and motivate

Getting workers to care about their hearing is the foundation for successful training.

Wearing hearing protection correctly is necessary for workers to prevent hearing loss. Because each worker may have different issues with hearing protector fit, work one-on-one on individual fit issues. See other training resources, such as NIOSH's Three Tips for Choosing the Right Hearing Protector or CPWR's Construction Noise and Hearing Loss Prevention Training Program for more recommendations and resources.

Tips for training workers about hearing protection

- If workers need to use hearing protectors, make sure they know where to use them and how to use them correctly

- Train management as well as workers

- Identify unique motivations for each group to prioritize hearing safety

- Regularly re-evaluate and implement additional training if needed