Key points

Use the manual method to understand blind areas around your own equipment. NIOSH created this alternative method for creating blind area diagrams quickly.

What it is

NIOSH evaluated strategies to prevent workers from being struck by construction vehicles and equipment in roadway work zones.

Evaluation methods required the use of blind area diagrams. NIOSH contracted with Caterpillar, Inc. to use standard test methods for creating these diagrams. NIOSH also developed a manual method for creating diagrams quickly. The manual method does not require specialized apparatus or software, and it does not require a particular location.

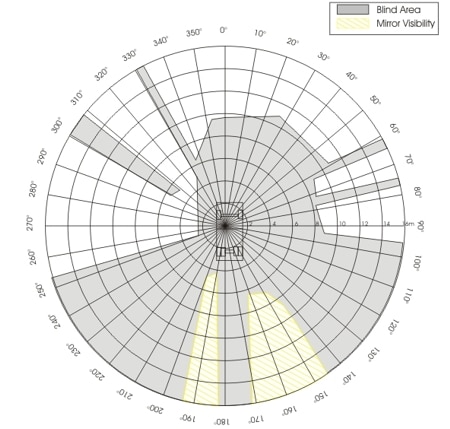

Blind areas are where the equipment operator cannot see objects by direct line of sight or mirrors. Three objects are of interest: the ground, a road construction barrel, and a worker. This results in plots that define visibility around objects at the following heights:

- Ground level

- 900 mm (3')

- 1500 mm (4'11")

Prepare the test site

Use a flat area at least 24 m on each side. A gravel or asphalt parking lot will work. Check that the area is clear of large debris.

With a surveyor's transit, mark a polar grid on the test site. Use stakes, spray paint, paint stick markers, or another immobile marker.

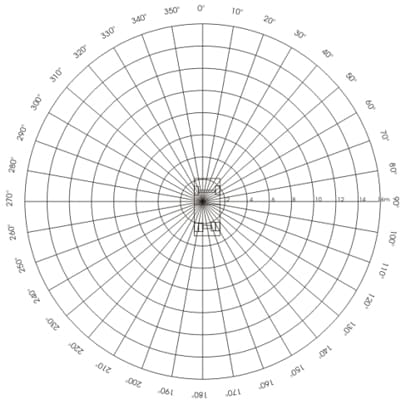

The polar grid consists of 16 m long lines. These radiate from the grid center at 10-degree intervals and a series of concentric circles, centered on the grid at 2-meter intervals (see Figure A-1). The outer circle has a 16 m radius. To measure for oversized equipment, you may need additional circles with larger radii.

Blind area mapping crew

The blind area mapping crew includes a driver, observer, recorder, and two point measurers. An additional recorder helping the two point measurers increases mapping efficiency.

Equipment preparation

To record blind areas, an average-height driver (1715 mm) provides feedback on visible areas.

The driver adjusts mirrors and seat height in accordance with the equipment operator's manual. Move equipment over the test grid so the driver's seat is over the center. The 0-degree line should be in front of the driver, parallel with the equipment's long axis (see Figures A-1, A-2).

Make sure the engine is off, the parking brake set, and the tires blocked. Set attachments (e.g. buckets, blades) as they would be when moving the equipment. Block them in place.

Marking blind areas

During tests, the driver remains seated in the cab in a normal driving posture.

It is important that the driver remains as still as possible. The driver may:

- Turn their head and torso (not beyond normal driving posture)

- Look (but not lean) out windows

- Use mirrors that are standard for the piece of equipment

If there are after-market mirrors, you can record areas visible using these mirrors but should note as such.

Ground visibility

To determine where the driver cannot see the ground, an observer walks along the radial grid lines and marks areas that the driver identifies. The observer starts at the 0-degree line as close to the equipment as possible. While the observer walks along the line and away from equipment, the driver signals when the bottom of the observer's shoes become visible. The observer then uses a level rod or other pointing device to find the exact location where the driver can see the ground. A mark is placed on the ground at each point that a transition occurs between visible and not visible. The mark can be made with spray paint, chalk or a removable marker such as a small wood block (see Figure A-3). The observer then continues to mark points along this line where necessary. When the 12 m radius is reached, the recorder moves back to the equipment and walks the next degree line. As the observer marks points on the ground, points are recorded on a polar plot, such as shown on Figure A-1, by a recorder (a scaled outline of the actual equipment, superimposed on the graph, is helpful, but optional).

As the observer walks each degree line and progresses around the truck, it may be necessary to mark additional points while estimating intermediate degree lines or radius marks. This helps to define the exact nature of the blind area. Some blind areas fan out to infinity. If so, shorten the process walking to the outermost circle and marking its transition points. For example, in Figure A-4, the right edge of the windshield creates a blind area that extends out toward 60 degrees. As the observer walked the 60-degree line, a marker was placed at 10.5 m indicating the first point at which the driver could see the ground. Because this area was recognized as a blind spot that extended out to infinity, the observer immediately went out to the outermost circle to determine where this blind area began (61 degrees) and ended (65 degrees).

The initial test is complete after all degree lines have been tested; however, the blind areas need to be better defined. To do this, the observer tests intermediate points between markers where necessary. Interpolation between markers results in a more accurate outline.

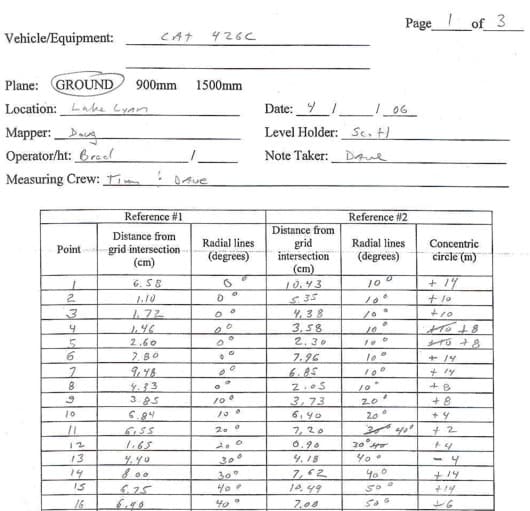

After verifying and refining the blind area marks, the two point measurers record the polar coordinates of the marks made on the ground by the observer. Each mark lies within or on a sector of the grid, defined by two circles and two radial lines (the circles are 2 m apart, the lines 10 degrees apart). Of the sector's four corners, the two closest to the center of the grid are used for measuring the polar coordinates for each blind area mark. When measuring cannot be achieved using the inner two corner points (e.g. machinery obstructs the measuring process), the outer grid points can be used. Coordinates are recorded on data sheets using polar grid points as references (see Figure A-5).

Construction barrel and worker visibility

The method for determining where a construction barrel and worker cannot be seen is similar to the above procedure. Instead of using the bottom of the observer's shoes and bottom of a level rod, place a mark on the level rod at 900 mm (barrel) or 1500 mm (person). The observer holds the pole in an upright position and places it on the test area grid points. The driver indicates to the observer whether or not the mark can be seen. A marker is then placed at the bottom of the level rod to mark the spot on the ground where each visibility transition occurred. The marks are then recorded as before.