Engineering Controls Database

Control Technology for Removing Lead-based Paint from Steel Structures: Abrasive Blasting Inside Two Ventilated Containment Systems

| Workers in the steel structure painting industry (e.g., bridges) doing abrasive blasting are at risk of high exposures to potentially hazardous levels of lead and silica. In addition to abrasive blasters and support personnel, site clean-up workers may also be exposed when containment structures (which may contain or be contaminated with residual lead and silica particles) are dissembled and moved or when handling abrasive and waste materials. High exposure levels have also been observed for auxiliary equipment workers and for those cleaning up the site after paint removal was completed. | |

|

Lead: It does not matter if a person breathes in, swallows, or absorbs lead particles, the health effects are the same; however, the body absorbs higher levels of lead when it is breathed in. Within our bodies, lead is absorbed and stored in our bones, blood, and tissues. Acute exposure to lead may cause abdominal pain, constipation, headache, irritability, loss of appetite, memory loss, or nausea. Since symptoms may occur slowly or may be caused by other things, lead poisoning can be easily overlooked as their cause. Being exposed to high levels of lead may cause anemia, weakness, and kidney and brain damage. Retardation has also occurred in children whose parent(s) may have job-related lead exposure. Very high lead exposure can cause death. Chronic exposure to lead may lead to risk of at risk for high blood pressure, heart disease, kidney disease, and reduced fertility. The Department of Health and Human Services [DHHS 2007] and the International Agency for Research on Cancer (IARC) have determined that lead is probably cancer-causing in humans. Silica: Overexposure to respirable crystalline silica dust can has been associated with development of silicosis, lung cancer, pulmonary tuberculosis, and airways disease. IARC reviewed the published experimental and epidemiologic studies of cancer in animals and workers exposed to respirable crystalline silica and concluded that there was sufficient evidence to classify silica as a human carcinogen (IARC 1997). Silicosis is also a fibrosing disease of the lungs caused by the inhalation, retention, and pulmonary reaction to the crystalline silica. When silicosis becomes symptomatic, the primary symptom is usually dyspnea (difficult or labored breathing and/or shortness of breath), first noted with activity or exercise and later, as the functional reserve of the lung is also lost, at rest. Once contracted, there is no cure for silicosis. The goal, therefore, is to limit worker exposure to respirable dust to prevent development of these diseases. |

|

|

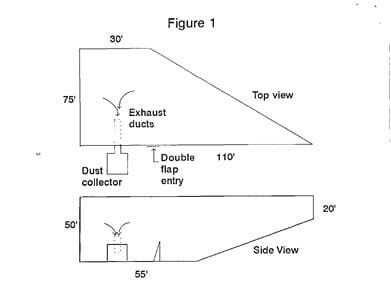

The first control system consisted of abrasive blasting with low silica (<1% by weight) sand, Star Blast XL (EI DuPont DeNemours and Company, Inc., Wilmington, DE) in a large enclosure made of interconnected canvas tarps suspended from the top of the roadway down to the ground, creating a room with a volume of 200,000 cubic feet. Within the left half of the containment the overpass was 50 feet above the ground. From the middle of the containment the ground sloped up to the right so that the far side of the overpass was 20 feet above the ground (Figure 1). The enclosure was ventilated by two 20-inch diameter exhaust ducts which were suspended from a light pole; this placed the duct openings approximately 12 feet above the ground. There were unplanned openings (most were at ground level where the tarps were not adequately fastened to the ground tarps) that acted as supply air inlets. Figure 1 shows a top and side view of the large containment and accompanying exhaust system. The Star Blast abrasive was used one time and allowed settle to the floor tarps along with other wastes created by the paint removal process, then it was collected for disposal.  The second system of abrasive blasting with recyclable steel grit in a 3,000 ft3 enclosure (8’X8’X48’) made of an alloy piping for the frame, rigid corrugated polycarbonate panels for the sides and an aluminum grating floor. The enclosure was suspended from two I-beams under the bridge (Figure 2). The small enclosure had a supply air fan at one end and an exhaust duct with a fan at the other end. The sloping walls under grate flooring directed the used abrasive and wastes to the bottom center of the containment area where the materials were removed from the containment. The steel grit was air washed using a recycle machine (IPEC Advanced Systems, North Kingston, RI) and reused. In both the large and small containment, the workers donned a single-use dust respirator under a continuous-flow, loose-fitting hood respirator prior to entering the containment and did not remove the respirator inside the containment.  NOTE: The control information in this engineering control write-up is taken directly from the following publication: Mickelsen LR, Froehlich PA [1994]. Control technology for removing lead-based paint from steel structures: abrasive blasting inside two ventilated containment systems. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH), ECTB 183-14a. |

|

| 183-12-A; 183-13-A; 183-14-A; 183-15A; 183-16-A; 183-17-A; 183-22; | |

|

DHHS [2007]. Toxicological profile for lead (update) Public Health Service Agency for Toxic Substances and Disease Registry. U.S. Department of Health and Human Services. IARC [1997]. IARC monographs on the evaluation of carcinogenic risks to humans: silica, some silicates, coal dust and para-aramid fibrils. Vol 68. Lyon, France: World Health Organization, International Agency for Research on Cancer. |

|

|

abrasive blaster abrasive blasting auxiliary equipment operators blaster helper paint removal site clean-up workers steel structure painting industry |

|

|

The large containment dilution ventilation system is almost of no value in reducing airborne lead exposures for those workers performing abrasive blasting inside the containment. The lead exposures were as high as 24,000 µg/m3 (geometric mean of 6,200 µg/m3) and smoke tube tests of containment air movement were negligible. The small containment dilution ventilation system was effective in moving air as shown by smoke tube tests but this air movement did not result in significantly lower lead exposures which were as high as 58,000 µg/m3 (geometric mean if 20,000 µg/m3). Workers inside the large or small containment structures during dry abrasive blasting may be exposed to airborne lead concentrations in excess of 100 times the OSHA PEL for lead. The continuous-flow loose-fitting hood respirator with an Assigned Protection Factor (APF) of 25 would not be the respirator of choice for this application because of the high airborne lead levels. Additional engineering controls (e.g., automation, local exhaust, or dust suppressants) and work practices should be developed and used to reduce the lead concentration inside the containment systems during abrasive blasting. In the interim, as more effective techniques and work practices are developed, a comprehensive respirator program providing for good worker training, use and storage of respirators and enforcement of the respirator programs could improve the protection of workers. Additional research is needed to evaluate the exposure effect of replacing the loose-fitting respirator with a tight-fitting respirator in this work environment. Environmental monitoring should be routinely performed to measure worker exposure to airborne lead and other hazards (e.g., silica). Respiratory protection must be selected based on measured airborne hazards for each job type. Support personnel wearing only half-mask respirators should not enter the containment during or immediately after the blasting process and must limit the time spent near the containment areas where lead exposures are high. Change rooms with showers and washing facilities need to be provided and used. Based on the levels of airborne lead near the large containment and results from previous studies reporting lead containment on workers hands, any should be no smoking prior to hand washing or smoking near the containment area. Respirators should be stored in a clean area when they are not in use. It is recommended that employers re-enforce their hygiene program by routinely encouraging workers with walk-through and verbal contact during the work day. Contaminated clothing should be laundered by the employer and laundry should be informed that the clothing is contaminated with lead dust. |